windorflex

(512) 931-1962

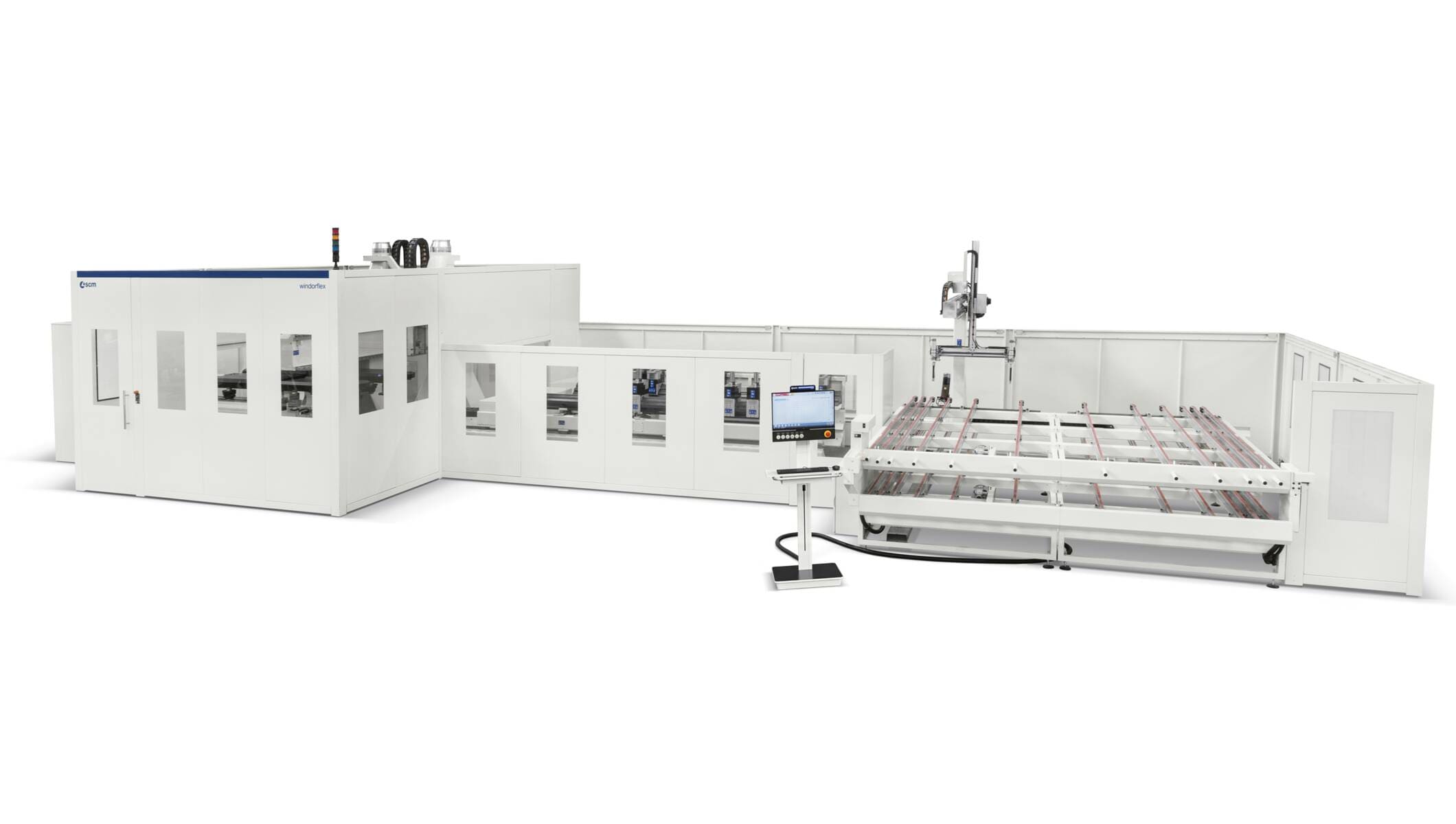

Windorflex is the SCM machining cell for windows and doors manufacturing.

It is an innovative and high-tech solution designed to perform all the necessary operations for producing window frames, regardless of the type.

The automatic work-pieces loading/unloading systems enable the machine to work autonomously, without the continuous input of the operator. These systems are available in two solutions: with loading/unloading bench or with an anthropomorphous robot.

HIGH PRODUCTIVITY

The automatic worktable, available in single or double version, is equipped with dedicated clamps for the constant holding of the work-pieces. It is possible to process from 1 to 4 work-pieces in sequence.

BEST-IN-CLASS PERFORMANCE

The configurability of the machining units with 4 and 5-axis electrospindles, allows performing all the necessary operations for windows production.

COMPLETE PROCESS

The automatic system with front or side bench, reduces the operator interventions during loading and unloading operations of work-pieces.

It can be fitted with one or two handling devices.

| windorflex 1 | windorflex 2 | |||

| Max. work-piece length | mm | 1 x 3500 2 x 1700 1 x 4500 3 x 1245 1 x 6000 4 x 1160 |

2 x 3500 4 x 1700 2 x 4500 6 x 1245 2 x 6000 8 x 1160 |

|

| Min. work-piece length | mm | 220 160, with specific cycle |

||

| Max. work-piece width | mm | 260 | ||

| Min. work-piece width | mm | 40 | ||

| Max. work-piece thickness | mm | 160 | ||

| Min. work-piece thickness | mm | 35 | ||

| X-Y-Z axes max. speed | m/min | 100-80-50 | ||

| Standard electrospindles motor power | kW | 20 | ||

| Standard tools stores | n. - positions | 1 x 48 | 2 x 48 | |

Fill out the online form to be contacted by a salesperson